PRODUNT

Magnesium alloy CP

Aluminum alloy CP

Zinc alloy CP

Reference electrode

Test Stub

Thermite flux

Power impressed anode

Auxiliary materials

News

- What is a sacrificial anode

- Basic requirements for reference...

- What does the reference electrode do...

- Why are zinc blocks attached to the ...

- What is the principle of impressed...

- What material does metal structure...

Contact

Phone:18739187123

hotline:0391-7588881

E-mail:970512272@qq.com

Address:Wuzhi County, Jiaozuo City, China

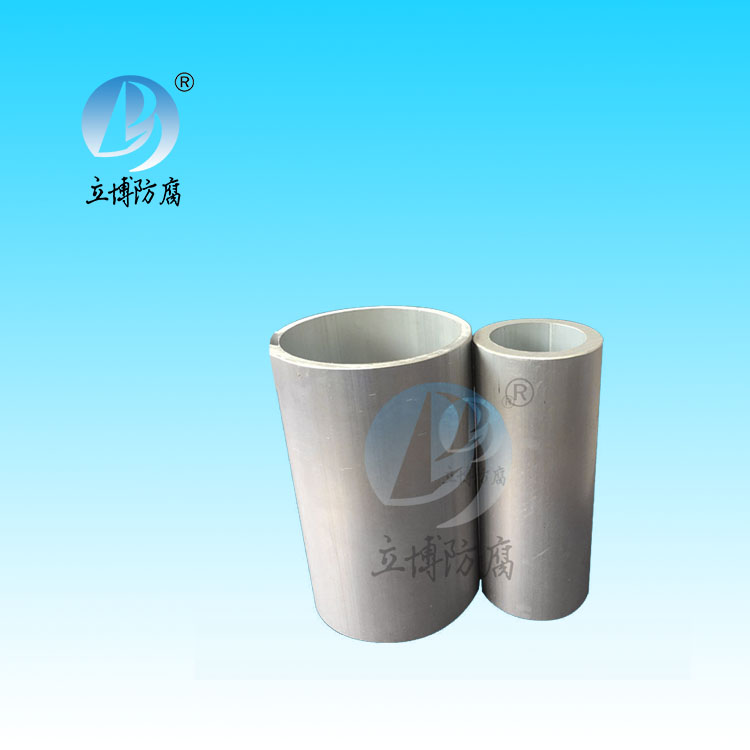

casing aluminum anode

Type:Aluminum alloy CP

Features:Structure and working principle of casing anode: it is composed of metal body and alloy anode. An anode protector is used to provide an anode to the surface of the casing to be protected, so that the anode alloy is sacrificed, so that the casing (cathode) to be protected is reduced or mitigated from corrosion.

Release DATE:2021-06-29

Corrosion is in the process of oilfield development effect on production and wellbore oil and water Wells is very serious phenomenon, caused by oil and water Wells casing corrosion perforation of oil and water Wells is scrap, all kinds of pipeline corrosion perforation, equipment corrosion and frequent replacement and scrapping, underground pipe rod pump, shorten operation cycle and so on, causes because of corrosion damage were bring huge economic losses to the production of oilfield.Corrosion is the nature of the metal surface ionizes the atoms, the corrosion electric chemical is more apparent in the electrolyte, the ground of the oil field using underground pipe is in the ground or in well liquid electrolyte solution, due to the metal surface corrosion of metal caused by the galvanic effect between, is an obvious feature of oilfield corrosion.In particular, the electrochemical corrosion caused by different metal materials used in oil and water Wells is especially obvious.

Product type: casing aluminum anode

Scope of application: This product is applied to new drilling and lateral drilling,is characterized by casing through the salt paste layer and other media corrosion strong new drilling and lateral drilling casing corrosion protectionStructure and working principle of casing anode: it is composed of metal body and alloy anode. An anode protector is used to provide an anode to the surface of the casing to be protected,so that the anode alloy is sacrificed, so that the casing (cathode) to be protected is reduced or mitigated from corrosion.

Casing anode appearance size:

¢139.7mm specification casing matching anode: ¢168*142.5mm, length 500mm;

¢114.2mm specification casing matching anode: ¢140*116mm, length 500mm;

Anodic casting shall not have pores, sand holes, the appearance of silver white, smooth surface.

Anode inner diameter dimension tolerance ±0.05mm

Locking force > 3 tons/piece.

¢139.7mm specification casing matching anode locking card: ¢168*142.5, length of 120mm;

¢114.2mm specification casing matching anode locking card: ¢140*116, length of 120mm;

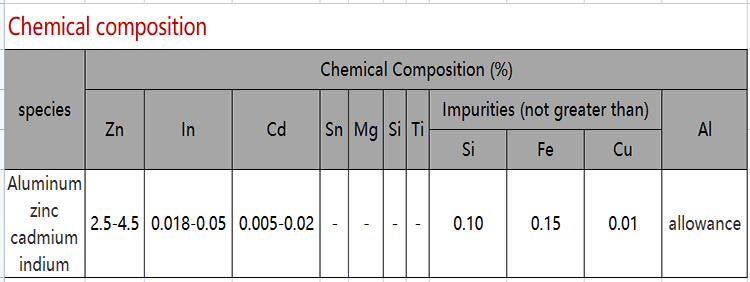

Main chemical components:

Aluminum alloy sacrificial anode chemical composition

Corrosion is in the process of oilfield development effect on production and wellbore oil and water Wells is very serious phenomenon, caused by oil and water Wells casing corrosion perforation of oil and water Wells is scrap, all kinds of pipeline corrosion perforation, equipment corrosion and frequent replacement and scrapping, underground pipe rod pump, shorten operation cycle and so on, causes because of corrosion damage were bring huge economic losses to the production of oilfield.Corrosion is the nature of the metal surface ionizes the atoms, the corrosion electric chemical is more apparent in the electrolyte, the ground of the oil field using underground pipe is in the ground or in well liquid electrolyte solution, due to the metal surface corrosion of metal caused by the galvanic effect between, is an obvious feature of oilfield corrosion.In particular, the electrochemical corrosion caused by different metal materials used in oil and water Wells is especially obvious.

客服QQ

客服QQ