PRODUNT

Magnesium alloy CP

Aluminum alloy CP

Zinc alloy CP

Reference electrode

Test Stub

Thermite flux

Power impressed anode

Auxiliary materials

News

- What is a sacrificial anode

- Basic requirements for reference...

- What does the reference electrode do...

- Why are zinc blocks attached to the ...

- What is the principle of impressed...

- What material does metal structure...

Contact

Phone:18739187123

hotline:0391-7588881

E-mail:970512272@qq.com

Address:Wuzhi County, Jiaozuo City, China

High silicon cast iron anode

Type:Power impressed anode

Features:It is an auxiliary anode material widely used in impressed current cathodic protection system because of its strong acid and corrosion resistance

Release DATE:2021-06-22

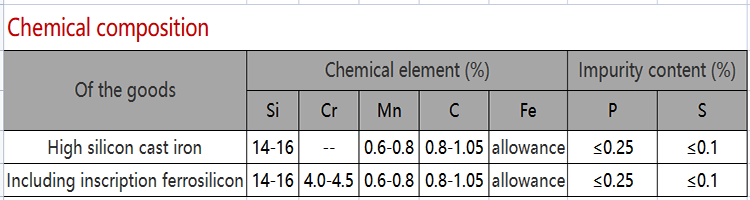

High silicon cast iron anode with chromium is an ideal auxiliary anode for impressed current cathodic protection system.Widely used in oil, natural gas, chemical plants, water companies and other underground or water metal structure protection and corrosion prevention.The high silicon cast iron anode of our company is manufactured according to gb8491-87 standard.

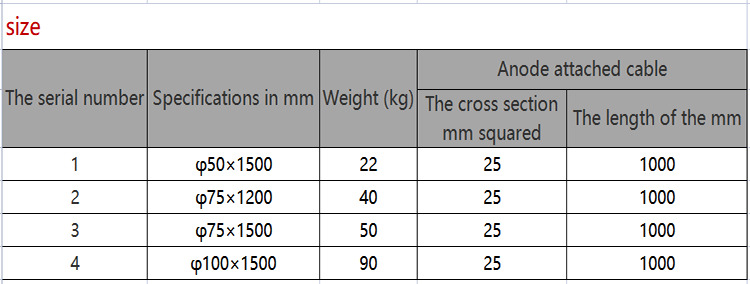

product type:High silicon cast iron anode

executive standard:SYJ36—89

Main performance:It is an auxiliary anode material widely used in impressed current cathodic protection system because of its strong acid and corrosion resistance

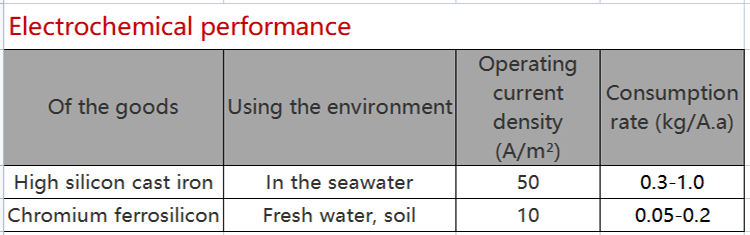

main application:High silicon cast iron anode is widely used in the cathodic protection of impressed current of offshore oil drilling platform, underground pipeline, underground cable and other facilities. High silicon cast iron anodes of various types of rod and tube can be supplied

Product introduction:

High silicon cast iron anode with chromium is an ideal auxiliary anode for impressed current cathodic protection system.Widely used in oil, natural gas, chemical plants, water companies and other underground or water metal structure protection and corrosion prevention.The high silicon cast iron anode of our company is manufactured according to gb8491-87 standard.

Product Characteristics:

1. Low consumption rate and high allowable current density

2.Low grounding resistance, stable polarization potential and high utilization rate

Instructions:

1. High silicon cast iron anode high silicon content, do not collision during transportation and installation.When installing the anode, do not use the anode conductor as the lifting tool, so as not to cause damage such as the increase of resistance of the joint and the separation of the conductor and anode.

2. High silicon cast iron anodes should be installed in such a place that the protection current is evenly distributed.When used in soil, coke should be used as filler and the maximum particle size of coke should be less than 15mm.

3. The distance between the high silicon cast iron anode and the pipe is between 50 ~ 300m.

4. High silicon cast iron anode no matter which form is installed in vertical or horizontal, the distance between vertical anodes is generally 3m, the distance between the vertical anode is generally 3m, and the horizontal anode is arranged in a line, the interval is 0.3 ~ 1m.

5. When the high silicon cast iron anode is used with the anti-corrosion instrument, the anode is connected to the positive electrode of the instrument, and the protected body is connected to the negative electrode of the instrument.

客服QQ

客服QQ