PRODUNT

Magnesium alloy CP

Aluminum alloy CP

Zinc alloy CP

Reference electrode

Test Stub

Thermite flux

Power impressed anode

Auxiliary materials

News

- What is a sacrificial anode

- Basic requirements for reference...

- What does the reference electrode do...

- Why are zinc blocks attached to the ...

- What is the principle of impressed...

- What material does metal structure...

Contact

Phone:18739187123

hotline:0391-7588881

E-mail:970512272@qq.com

Address:Wuzhi County, Jiaozuo City, China

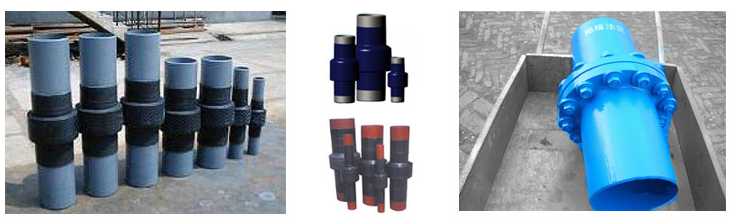

Insulation joint

Type:Auxiliary materials

Features:Mainly used in oil, natural gas, hydrocarbons, water, steam and corrosive liquid and other media of the transmission pipeline corrosion cathodic protection.

Release DATE:2021-06-22

This product is mainly used in the cathodic protection of oil, natural gas, hydrocarbons, water, steam and corrosive liquids and other media in the pipeline corrosion protection. Different pipe materials can be used according to user requirements, such as: high strength carbon steel, austenitic stainless steel, double joint; Mixed connections can also be used with different pipes, such as carbon steel and stainless steel, steel and copper, steel and titanium, etc. The terminal of the overall pipe insulation joint has been processed in the factory, there are a variety of connection methods for users to choose: such as flange connection, threaded connection, threaded connection with valve and welding connection.

Product type: Insulation joint

Main performance: good insulation

performance, long life, high strength.

Scope of application: Mainly

used in oil, natural gas, hydrocarbons, water, steam and corrosive liquid and

other media of the transmission pipeline corrosion cathodic protection.

Detailed introduction:

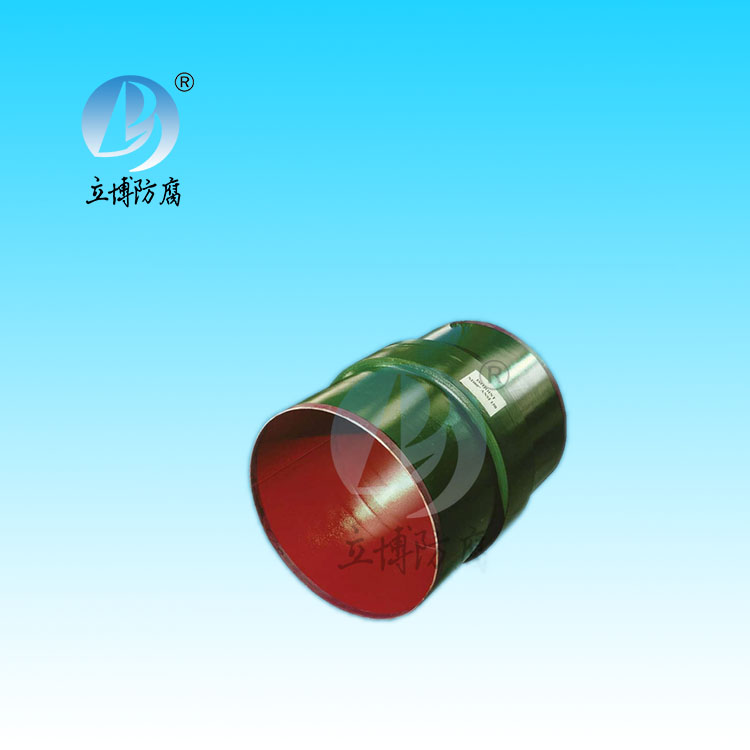

Insulation joint is a general term for pipes and pipe joints that have the sealing performance, strength performance and electrical corrosion resistance required by buried steel pipelines. It includes assembly, insulation board, packing, sealing ring, short pipe, etc.

Insulation joint is an improved product based on the problems existing in the use of insulation flanges. It is an essential and important pressure element in the cathodic protection system of steel pipelines and is widely used in the cathodic protection system of steel pipelines. Referring to the structure of the latest foreign products, the insulation joint of our company adopts the unique design to overcome the disadvantages of the insulation flange, such as small stiffness, easy leakage, not buried in the ground, short life, etc., and realize the function of buried maintenance free, so that the service life of the insulation joint is the same as that of the supporting pipeline.

Insulation joints shall be welded by integral extrusion, and bolts and flanges shall not be used. The insulation joint is in the form of clamping and fixing the insulating and sealing materials into the sleeve (assembly). After the insulation joint is assembled, the internal component should be fixed in the corresponding position. The entire insulation joint shall remain intact under soil pressure, specified pipe operating pressure and plant or field hydrostatic testing. The sealing element of the insulating joint is close to the insulation board inside the joint and has permanent elasticity, and both sides of the sealing element are in direct contact with the exposed metal surface without moving, ensuring the tightness of the joint.

This product is mainly used in the cathodic protection of oil, natural gas, hydrocarbons, water, steam and corrosive liquids and other media in the pipeline corrosion protection. Different pipe materials can be used according to user requirements, such as: high strength carbon steel, austenitic stainless steel, double joint; Mixed connections can also be used with different pipes, such as carbon steel and stainless steel, steel and copper, steel and titanium, etc. The terminal of the overall pipe insulation joint has been processed in the factory, there are a variety of connection methods for users to choose: such as flange connection, threaded connection, threaded connection with valve and welding connection.

Product features:

Good insulation performance: the insulation resistance is 10M ω, which can improve the service life of the protected pipeline.

Long life: the same life and strength as the pipeline;

High strength: the use of secondary sealing structure, coupled with the injection of polymer composite material in the annular space between the two flanges, and pipeline life, than the life of insulation flange increased many times;

Buried installation: there is no need to set an observation well for underground installation, and it can be directly buried underground;

Automatic lightning protection: the automatic protection structure can be set according to the user's requirements. When the induced charge reaches a certain value, it starts to discharge, and automatically restores the insulation after lightning strike. Dynamic recovery source insulation;

Operating temperature: -30℃ -- +90℃.

Applicable medium: oil, gas, water, chemical raw materials, coal slurry, etc.

Technical characteristics: Size: DN15 ~ DN1200;

Pressure level: PN1.0 ~ PN40Mpa;

Service life: same as pipeline;

Applicable medium: oil, gas, water, chemical raw materials, pulp applicable.

Quality requirements: insulation resistance: 1000V DC resistance value ≥6M ω;

Insulation strength: 2500V 50Hz 1 minute without breakdown or arc;

Hydraulic test pressure: 1.5 times of the design pressure;

Airtight test pressure: equivalent to the design pressure;

Nondestructive testing: 100% ray testing for all butt joints and 100% magnetic particle testing for other pressure welds according to JB4730-94;

Groove: adopt API5L standard.

Material characteristics:

Assembly: according to JB4726-2000 16Mn ⅱ (pressure class < 6.4mpa);

16Mn ⅲ (pressure grade ≥ 6.4mpa);

Short pipe: same as pipeline material;

Insulating material: high strength epoxy glass laminated cloth board;

Filling material: high strength epoxy resin;

Sealing material: rubber fluorine 26;

Anti-corrosion insulation material: two - component solvent-free epoxy coating, anti-corrosion heat shrink sleeve.

Installation requirements:

1. Insulation joint installation within 50 meters, to avoid welding dead;

2. After the insulation joint is connected with the pipeline, do not lift the pipeline within 5 meters of the joint;

3. Test the pressure of the insulation joint with the pipeline.

客服QQ

客服QQ